I really like this new phase (wiring), although there is still some work that I have to do on the hood, I'm just putting it off for now while my focus has changed to the wiring so I can start the engine. I've owned this engine far too long for it not to be running. The justification is that the internals need oiling to keep from rusting. How's that.

This is an older photo showing the throttle body prior to being installed on the intake.

|

Here is another older photo that shows throttle body as it is intended to be installed on the engine by General Motors. Then, attached to the front of the throttle body will be the mass air flow sensor and then and some type of air filter or air fliter ducting. My problem, in the 33 Ford, along with a ton of other hot rods, there isn't enough room between the intake manifold and the radiator for all of these parts. Therefore alterations are in order. |

In this photo, thanks to my mentor Jurgen B. for this great design and Brian G for the welding, I've been able to fabricate a 4" diameter tube that wraps back on top of the intake where I've now attached the throttle body. One thing I do have is a lot of room on top of the engine.

In this photo I've also attached the mass air flow sensor.

|

| This photo really shows the electronic throttle body attached between the fabricated tube and the mass air sensor. I've also attached the electronic wiring to to the throttle body. This wiring has replaced the old mechanical (rod or cable) throttle linkage typically seen on carbureted engines. |

Here is what I'll use as an air cleaner for the time being, but eventually I probably will make something very different.

|

| All of this will be placed under the dash, hopefully in some order. |

|

| This is the engine harness and computer portion of the previously seen wiring |

|

| This picture shows the canon plug on the back of the transmission. As with the engine, the 6L80E transmission is electronically controlled. The computer or ECM (electronic control module) also called ECU (electronic control unit) among other terms for this device, are inside the body of the transmission. Adjustments are made to the transmission and engine by attaching a laptop computer to the data port under the dash of the car. |

|

| Another picture of the transmission cannon plug. |

|

| Here is the engine ECM installed under the dash. Right in the center of the picture you can see (oval looking thing) where the plug attaches to the gas pedal. Once again completely electronically controlled. |

|

| Back to a little fab work. I've installed the third brake light in the tonneau cover. |

|

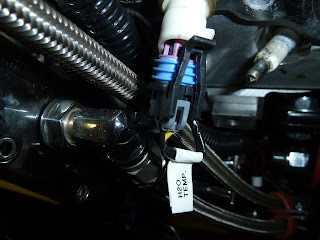

| Attaching the engine wiring is as simple as plugging a plug into a socket. Here you can see the socket (white) and the plug (purple and blue) for one of the two water temp probes. In addition to Current Performance labeling every plug, GM has made every plug and socket to a different configuration. I have to admit, there is absolutely no way to wire incorrectly, using the harness supplied by Current Performance. |

|

| Here the plug is inserted half way into the socket. |

|

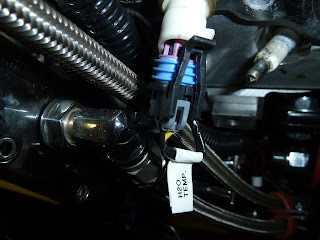

| Completely installed. Now, plug in the remaining 29 plugsi into their sockets and the engine should turn over. Right? |

|

| I installed the coolant overflow tank to the back side of the radiator. That's the long 2" cylinder. The reason I'm showing this is that it turned out to be a real big event. I originally thought I would be able to drill the holes for the attaching hardware after the radiator was installed but wrongo wrongo. It was impossible to get a right angle drill into position therefore out came the radiator, after removing the grill. Drilling the holes in the fan shroud then reinstalling the radiator and grill. |

|

| After all the work installing the overflow tank I thought it warranted at least two pictures. |

Eventually all of the engine wiring was in place and it was time to test the engine. This is a milestone for car builders.It definitely was for me. Although wasn't time to actually start the engine, as I wanted to turn it over a few times to get he oil moving around inside the engine.

.JPG)

.JPG)